I have seen that 4 times in the last year. Strange thing is when you ask what happened and see some evidence - the piston is never to blame!

Modern pistons almost never fail and when they do they explode and blow a rod out the side of the motor at 15 thousand rpm - generally a memorable

occasion; they do not melt without the owner/restorer/assembler/tuner being at least partially to blame.

I would like to share some thoughts and photos with you so you can avoid having to say those words.

The basics

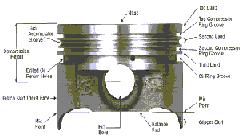

This is a modern forged piston.

Its environment:

Pistons are cooled partially by heat conduction through the rings to the cylinder walls, by oil splash from the sump and by the incoming air/fuel charge.

Materials:

Aluminum, alloyed with copper, magnesium, nickel and silicon are common piston alloys in use today.

Silicon is the major alloying element added to the aluminum. It offers better strength and expansion.

Piston types:

Die cast:

- This process requires the melting of a high silicon alloy in an electric furnace to around 700 C.

The molten alloy is then poured into a multi-piece cast iron die and allowed to solidify slowly; producing a very accurately shaped piston casting.

After the casting has cooled; they are tempered to improve its qualities.

There is a sub-class of cast pistons that are poured in an inert gas environment so as to give fewer impurities and so are less inclined to start cracking.

Most modern Japanese bike OEM pistons are made this way.

There is another sub-class of cast piston called hypereutectic. This is a high silicate cast piston.

The result is a light cast piston having nearly the strength as a forged piston combined with the desired hardness and low expansion rates of a typical

cast piston. Hypereutectic aluminum has 15% less thermal expansion than conventional piston alloys. Hypereutectic pistons are a low-cost alternative

to forged pistons for certain original equipment engine applications requiring something better than an ordinary cast piston.

I don't think they are available in bike pistons.

Die casting alloys: A 10% silicon aluminum alloy F132 is normally used.

The hypereutectic uses a higher silicon alloy called 390.

Die Forged:

An alloy slug close to the final outside diameter is pre-heated in an air-circulating furnace to a temperature quite close to the operating temperature of the

piston crown when the engine is operating at full power. The forging press then presses it into a die. After forging, any excess material is removed and

the forgings are then tempered.

Die forged alloys: There are two common alloys used in forged pistons. 2618A aluminum alloy is the most commonly used material. The quality of this is

enhanced depending on what sort of tempering has been applied.

Normally, T6, which can increase the strength of the alloy by as much as 30%. This is, in my opinion, the lowest acceptable quality to use in a vehicle

using modern fuels.

2618-alloy pistons keep their shape under extreme pressures and high rpm's.

4032 - High silicon-aluminum alloys such as this have great wear characteristics because the silicon particulate hardens the alloy and reduces the thermal

coefficient of expansion. However, they can turn brittle and become prone to catastrophic failure fracturing when a crack starts.

Low- or no-silicon alloys, such as 2618, may wear a bit faster but provide better strength and durability.

In the rare case of a crack in a 2618 piston, the crack will migrate to an area of lower stress and stop.

Then they all are machined in a CNC machine centres. And end up looking like the picture below.

A forging on the left, and a casting on the right.

Note how the forging has a smooth eggshell finish and the casting has ribs and lines, some to assist the casting process and others formed due to the casting

tool being made of around nine different

Which is better?

Let the arguments begin!

I really don't think there is a better or worse.

There are lots of bikes - really fast revving modern ones too - running round with cast pistons.

I think there is a right type and this depends on the type of stresses you are going to put your motor to.

Below I have listed some benefits of each:

Cast:

· Cost. The cost of a cast piston is considerably less than that of forged one. Anywhere from 30-80% less.

· Purpose - Stock cast aluminum pistons are fine for stock engines.

· Oil oxidation - A cast will have less "blowby" into the sump on starting which will reduce oil degradation.

· Expansion - a cast piston is more thermically stable than a forged because they have more silicon; and so can run closer tolerances.

· Noise - less noise on start up because of the clearances.

· Heat - a cast piston will have less ring-groove wear and have marginally less heat conductivity, keeping more heat in the combustion chamber.

This can be a problem though if there is an inclination to pre-ignition.

See below.

Forged:

· Stronger. The difference in strength between forged and cast pistons is considerable.

They can withstand loads anywhere from 40% to almost 100% higher than cast because the forging process makes the metal more ductile.

· Mass - the forged is lighter by about a third than cast. This makes a big difference at 7500rpm as lighter pistons can handle higher rpms with less

stress on the rods, crankshaft and block.

· Durability - the forged will take far more abuse without breaking because of it's finer structure.

· Oil use - after warming up a forged piston will use less oil as it's thinner rings will seal better.

· More power - rings can account for up to 40% of an engine's internal friction. If they are thinner - less friction -less heat - more power.

· Detonation - casts are very intolerant of detonation especially around the ring lands. Forged pistons will conductheat of the crown faster than cast

because of the structure. Overheated combustion chamber parts start reacting as glow plugs.

Pre-ignition induces extremely rapid combustion and welding temperatures.

Melt down is only seconds away. So if you are in the habit of going to the red line a lot (try to change this - a standard Lav runs out of steam at around

7500 so going to 8300 is just making noise!) or riding long and hard on hot summer days, racing or your beast has been tuned to the tits - consider forged

pistons.

Otherwise casts are fine.

Pre-ignition and detonation problems should be fixed and their end result not blamed on the piston.

Failure: Right, to piston failures.

There are two types of failure that will happen in a Lav.

1. Piston melting - this is almost always caused by a leak in the inlet tract leading to severe leaning out, rapid increase in piston crown heat to above 600C

at which point the aluminum melts.

The damage will invariably occur on the inlet side of the piston.

Here are some cause and effect photos to explain:

This plucky beast ran on, spitting out bits of piston until it melted under the oil ring and lost all compression.

The piston and bore had smears of molten aluminum embedded into their sides and still it did not try to seize!

Look at the heat discolouration on the pin - this thing got really hot. No piston fault here!

This is what caused the problem.

First a isolation block from a triple was used.

These are too big for the flange of the twin and sit half on and half off the sealing O ring.

Which finally says bye bye and breaks. air gets in and combustion gas gets out - the black semi circle on the inlet runner tells us this.

The mixture goes lean and all the expensive bullshit above happens.

Another clever trick involves spending only $2 on an ordinary O ring instead of $5 for a Viton one. $3 saved and $3000 wasted, as modern fuels

will destroy the plain O ring and cause all the above bulllshit to happen.

I am in the process of getting some Viton gaskets made to suit Lav inlet runners.

So check for a lean fuel mixture.

A normal air: fuel ratio is around 14:1. If this rises just a bit the temperature on the piston crown will rise fast - till it is +600C and remember what happens

now - aluminum pistons melt.

Rich fuel mixtures resist detonation while lean ones do not.

Air leaks in intake manifold gaskets, cracked inlet runners, carburetor gaskets will all admit extra air into the inlet ide and lean out the air: fuel mixture.

Lean air: blocked carburetor jets, a restrictive fuel filter or too small a fuel rail can also cause fuel mixtures.

The last cause is really important on triple doing long protracted full throttle runs - like on a freeway or dyno.

If the fuel mixture becomes too lean, "lean misfire" may occur as the load on the engine increases.

This can cause a hesitation, stumble and/or rough idle problem as well.

Sound familiar? This is a big problem on some badly tuned triples.

Things to do:

· Are the runner nuts tight? Not over tight - this will deform the flange and it will leak!

· Are the isolator blocks the right size?

· Are they in good condition?

· Is the O-ring a Viton one?

· Does the inlet runner have cracks in it?

· Is the seal between the runner and carb good? No cracks?

A little test for all this. Start the bike and bring to operating temp. Set the idle at around 2000. Spray some carbon monoxide (fire extinguisher) - around

the runner flanges. If the motor speed decreases suddenly - it's leaking. Fix it.

2. Piston explosions are caused by pre ignition and detonation.

There is a difference. Detonation is an erratic form of combustion that can cause head gasket failure as well as other engine damage.

Detonation occurs when excessive heat and pressure in the combustion chamber cause the air/fuel mixture to auto ignite. This produces multiple flame fronts

within the combustion chamber instead of a single flame kernel.

When these multiple flames collide, they do so with explosive force that produces a sudden rise in cylinder pressure accompanied by a sharp metallic pinging or knocking noise.

The hammer-like shock waves created by detonation subject the head gasket, piston, rings, spark plug and rod bearings to severe overloading and heat.

· Pre-ignition is sometimes confused with detonation. This occurs when a point within the combustion chamber becomes so hot that it becomes a source of

ignition and causes the fuel to ignite before the spark plug fires.

This, in turn, may contribute to or cause a detonation problem.

Things to do:

Check for over-advanced ignition timing. Too much spark advance especially at low revs can cause cylinder pressures to rise too rapidly. This is a problem

with older CDI controllers on Lavs.

Solution - get a better igniter. "Read" your spark plugs. The wrong heat range plug can cause detonation as well as preignition.

If the insulators around the electrodes on your plugs appear yellowish or blistered, they may be too hot for the application. Try the next heat range colder

spark plug.

Copper core spark plugs generally have a broader heat range than ordinary plugs, which lessens the danger of detonation.

Check for engine overheating. A hot engine is more likely to suffer spark knock than one that runs at normal temperature.

Remove carbon deposits. An accumulation of carbon deposits in the combustion chamber and on the top of the pistons can increase compression to the point

where detonation becomes a problem.

Carbon deposits are a common cause of detonation in high-mileage engines, and can be especially thick if the engine consumes oil because of worn valve

guides and seals, worn or broken piston rings and/or cylinder wear.

Infrequent driving and not changing the oil often enough, using mineral oils can also accelerate the buildup of deposits.

So set your carbs up right.

Also make sure the thing is firing at the right time. Carbon deposits can often be removed from an engine that's still in service by using a chemical "top cleaner."

This type of product is poured into an idling engine through the carburetor or throttle body. The engine is then shut off so the solvent can soak into and loosen

the deposits.

When the engine is restarted the deposits are blown out of the combustion chamber.

Junk your oil straight after using this stuff.

Use good fuels.

We have found that this can be affected by leaks in the exhaust system too.

Tips and tricks:

1. Using spray on coatings. These were initially developed for NASA and military use. There are many different types available.

I use three.

Thermal barrier, solid film lubricants and internal exhaust coating. Thermal barriers on the hot bits will give the following benefits:

· Reduced heat transfer.

· Eliminate hot spots.

· Improve flame travel.

· Improve top ring sealing.

· Reduce ring temperature.

· Prevent carbon build up.

· Improved combustion chamber efficiency.

Solid film lubricants such as graphite moly-disulfide coating on the forged piston skirt will give the following benefits:

· Improved scuff resistance

· Tighter clearances between the piston and cylinder to reduce piston slap and blowby - oil oxidation on start up.

Here a two examples:

This is a piston for a triple. The crown has been coated with a ceramic thermal barrier and the skirt a graphite

moly-disulfide film. This means that cost is now the only benefit left to casts.

This is a twin plug head for a triple that has had the combustion chambers, inlet valve faces, exhaust valve heads

and the exhaust ports coated with a ceramic thermal barrier.

2. Attention to piston design will result in more power and less problems.

Two examples is top ring position and ring material selection.

A compression ring high on the piston cools the piston top more effectively, reduces detonation and increases Hp.

For applications where an engine is subjected to higher loads and operating temperatures, moly faced rings usually provide the best wear resistance.

Molybdenum also provides great scuff resistance and is porous, so it retains oil to keep the ring lubricated.

Moly also has a higher melting point than chrome or plain cast iron, which enables it to survive under the harshest operating conditions.

Compared to plain cast iron, chrome rings can cut wear by more than 50%.

Substituting plain cast iron rings in an attempt to hold down costs will sacrifice those advantages

3. Ring gaps and types. Simple stuff this?? Get it right and you'll have a more powerful and better-lubricated motor.

Read on.

Here is how rings work: When the combustion pressure over the top ring is greater than the pressure between the top and second ring, it forces the top

ring downward and outward to seal against the piston groove and cylinder.

But if pressure builds up between the two rings, it can prevent the top ring from sealing and increase blowby.

What some people don't understand is that the second ring is not really a compression ring but an oil control and vacuum ring.

One trick racers have long used to improve ring sealing is to open up the end gap of the second ring.

A wider end gap provides an escape route for blowby gasses that get past the top ring.

This prevents pressure from building up under the top ring and preventing maximum sealing.

Many second rings have a reverse-twist, taper face design that allows the ring to glide over the cylinder wall during the piston upstroke.

When the piston reverses direction, the sharp edge of the ring is forced out against the wall and acts like a squeegee to wipe off the excess oil. At the same

time, the second ring seals against the wall so the piston can pull as much vacuum as possible on the down stroke.

4. Squeezing it up. Improving the squish band.

The quench area is the flat part of the piston that would contact a similar flat area on the cylinder head if you had no clearance.

Lav twin have lots and triples buggerall.

By setting the assembled quench height of about 1mm (.040"); the shock wave caused by the piston rushing up to the head will drive the mixture through

the combustion chamber at high velocity.

This tends to cool hot spots, averages the chamber temperature, reduces detonation and increases power.

The squish (quench) distance is the compressed thickness of the head gasket plus the deck clearance (the distance your piston is down in the bore).

What I have done on the triple combustion chambers is to build a crown top that does this without help from the combustion chamber.

The only other way of doing this is to get an all aluminum head and weld in beside the valves.

Some Pistons Suppliers:

Accralite Pistons are forged in 2618A or 4032. They only make custom to order - do not expect them to carry stock. http://www.accralite.com/

Arias Pistons are forged from 2618 or 4032. Stock and custom designs UK and US

http://www.ariaspistons.com

KB Performance Pistons make hypereutectic pistons from 390 aluminum alloy. I don't know if they make bike pistons. http://www.kb-silvolite.com/

JE Pistons have 2618 or 4032 alloy available Uses TRW forgings. They make racing pistons. A High Quality made product, years of experience,

racetrack proven.

http://www.jepistons.com/

Mahle Pistons. Make for a few Formula 1 teams out of 142 high performance piston alloy. With an increased copper and nickel content, advantages

include improved dimensional stability over an engine's life and increased high temperature fatigue strength. Good selection of rings.

http://www.mahleinc.com/

JP pistons. Cast only. Good for vintage. Very cheap.

http://www.jp.com.au/

Manley Pistons. Forged trick 2618 racing pistons.

http://www.manleyperformance.com/

Pistons le Dauphin. Custom cast and forged. Brilliant selection of vintage racer pistons - NSU or 4 cylinder Gilera? http://www.pistons-le-dauphin.com/

Ross Pistons: Stock and custom designs. Their custom pistons are available for many applications that are not normally considered by any other company. 2618 or 4032 alloy available

http://www.rosspistons.com/

Wiseco Pistons: Stock and custom designs 2618 or 4032 alloy available

http://www.wiseco.com/

Or look here: http://www.ccdata.com/browse/